Availability optimization of bolts manufacturing plant using particle swarm optimization and genetic algorithm

Keywords:

Bolt manufacturing plant, Particle swarm optimization, Markov Birth-Death process, Genetic algorithm, AvailabilityAbstract

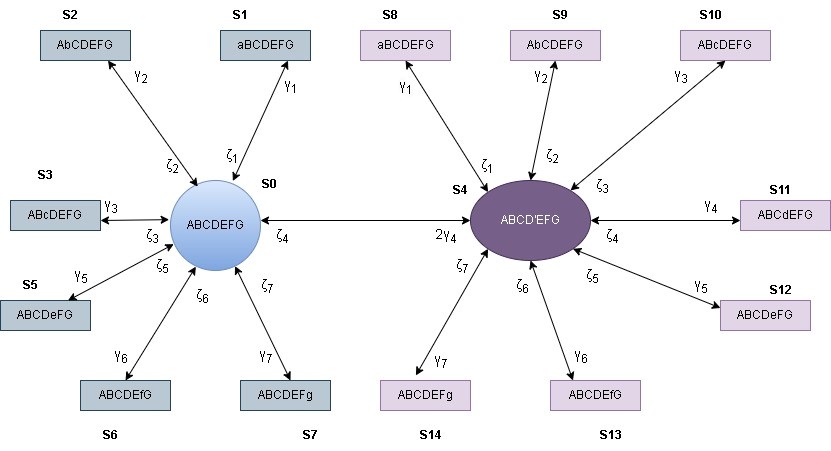

Availability plays an imperative role in the effectiveness investigation and performance evaluation of any manufacturing plant. The bolt manufacturing industry is one such plant. The present study is conducted with the motto of building a novel stochastic model of a bolt manufacturing plant (BMP) to derive availability along with its optimisation using metaheuristic approaches. The Markov birth-death process is adopted to build the stochastic model, as the breakdown and restore rates of the parts exhibit constant behaviour. The availability function is treated as an objective function of the optimisation problem, considering breakdown and restore rates as determination parameters. The availability function is optimised using particle swarm optimisation (PSO) and a genetic algorithm (GA) to forecast the optimal availability and estimated parametric values. The highly susceptible part of the system is observed after a 10% deviation in breakdown and restoration rates. It is viewed that the PSO algorithm predicts the optimal value of availability as 0.999429 after 30 iterations at 100 swarm size, while GA reached only up to 0.94791544 at a population size of 1000 after 100 iterations. The convergence rate of PSO is very fast in predicting the availability of plants. These results are valuable for organisational engineers and maintenance engineers to propose maintenance strategies. The suggested approach can be employed to predict the availability of other process industries.

Published

How to Cite

Issue

Section

Copyright (c) 2024 Monika Saini, Naveen Kumar, Deepak Sinwar, Ashish Kumar

This work is licensed under a Creative Commons Attribution 4.0 International License.

How to Cite

Most read articles by the same author(s)

- Monika Saini, Ashish Kumar, Vijay Singh Maan, Deepak Sinwar, Efficient and Intelligent Decision Support System for Smart Irrigation , Journal of the Nigerian Society of Physical Sciences: Volume 4, Issue 4, November 2022

- Kanak Saini, Monika Saini, Ashish Kumar, Dinesh Kumar Saini, Availability predictions of solar power plants using multiple regression and neural networks: an analytical study , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 2, May 2025