Mechanical Evaluation and Minerals Phases Identification of Fine and Coarse Okelele Block Clay Composites for Furnace Lining Application

Keywords:

Okelele clays, Kaolinite, Quartz, Refractory materials.Abstract

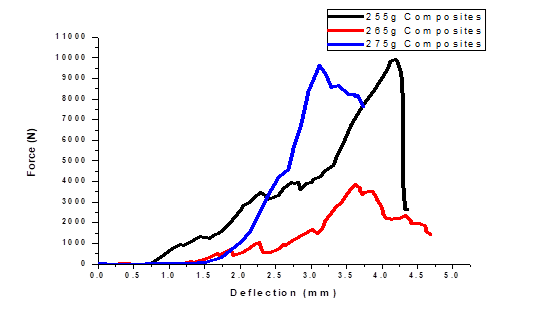

The suitability of fine and coarse Okelele clays as refractory raw materials for furnace lining application was investigated. The clay samples were crushed and pounded with a mortar and pestle to a particle size of 20 microns. 230 g each of fine clay was mixed with 50 mls of water inside a bowl and stirred thoroughly to form homogenous plastic paste. 10 g, 15 g, 25 g, 35 g and 45 g of coarse clay were added respectively to the 230 g of homogenous fine clay paste in different container. The fine and coarse clays composites weighing 240 g, 245 g, 255 g, 265 g and 275 g were respectively put in a mold of dimension 3 x 5 x 6 cm and air dried for 7 days. The samples were fired at temperature of 1200 oC for five hours using Carbolite Furnace. After cooling, the fine and coarse clay composites of 240 g and 245g were broken by the heat and composites blocks 255 g, 265g and 275g were hardened and remove for compressive test analysis. The fine and coarse clays were characterized using X-ray Diffractometer PW1830forminerals phases’ identification. The result of XRD shows that the clay was majorly composed of Quartz and Kaolinite with the traces of other minerals such as Smectile, Illite/Mica, Albite, Jarosite, Gypsum and Pyrite. The Kaolinite contains aluminum silicate (Al2O3·2SiO2) and Quartz has the silicon and oxygen atoms. The compressive strength test result judged the 275 g fire block of clays composite the best with the maximum force breaks of 7652 N with deflection of 3.734 mm and Young Modulus of 212 N/mm2 for the time to failure of 22 seconds. The results proved that Okelele clays are suitable as refractory material for furnace lining application.

Published

How to Cite

Issue

Section

Copyright (c) 2022 Journal of the Nigerian Society of Physical Sciences

This work is licensed under a Creative Commons Attribution 4.0 International License.

How to Cite

Similar Articles

- W. A. Yahya, A. A. Yahaya, A. A. Adewale, A. A. Sholagberu, N. K. Olasunkanmi, A DFT study of optoelectronic, elastic and thermo-electric properties of the double perovskites Rb2SeX6 (X=Br,Cl) , Journal of the Nigerian Society of Physical Sciences: Volume 5, Issue 2, May 2023

- Ogheneovo Akpoyibo, Ezekiel Onoriode Abriku, F. C. Ugbe, Ochuko Anomohanran, Geophysical and geotechnical assessment of Obiaruku-Agbor road failure in Western Niger-Delta, Nigeria , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 1, February 2025

- K. O. Sodeinde, S. O. Olusanya, D. U. Momodu, V. F. Enogheghase, O. S. Lawal, Waste glass: An excellent adsorbent for crystal violet dye, Pb2+ and Cd2+ heavy metals ions decontamination from wastewater , Journal of the Nigerian Society of Physical Sciences: Volume 3, Issue 4, November 2021

- Oluwole Adigun, Lasisi Egibunu Umoru, Temidayo Nancy Iwatan, Effects of different electrolytes on the structure and yield ofgraphene oxide produced via electrochemical exfoliation , Journal of the Nigerian Society of Physical Sciences: Volume 5, Issue 4, November 2023

- Emma Panzi Mukhokosi, Stephen Tenywa, Nandipha L. Bothab, Shohreh Azizi, Mathapelo Pearl Seopela, Malik Maaza, Green synthesis of CuO nanoparticles from Cucurbita maxima leaf extract; a platinum free counter electrode for dye sensitized solar cells , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 1, February 2025

- A. A. Faremi, S. S. Oluyamo, K. D. Adedayo, Y. A. Odusote, O. I. Olusola, Influence of Silicon Nanoparticle on the Electrical Properties of Heterostructured CdTe/CdS thin films based Photovoltaic Device , Journal of the Nigerian Society of Physical Sciences: Volume 3, Issue 3, August 2021

- A. M. Asere, T. O. Owolabi, B. D. Alafe, O. P. Alabi, M. B. Alimi, Assessment of Excess Gamma Dose Exposure Level in Typical Nigeria Commercial Building Materials Distribution Outlets , Journal of the Nigerian Society of Physical Sciences: Volume 3, Issue 3, August 2021

- Nassima Bou-ydia, Ben-issa El miraoui, Latifa Laallam, Ahmed Jouaiti, Interaction of hydroxyapatite and chitosan with gentamicin and their antimicrobial activities: DFT and molecular docking approach , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 3, August 2025

- N. K. Olasunkanmi, D. T. Ogundele, V. T. Olayemi, W. A. Yahya, A. R. Olasunkanmi, Z. O. Yusuf, S. A. Aderoju, Assessing leachate contamination and groundwater vulnerability in urban dumpsites: a case study of the Ipata Area, Ilorin, Nigeria , Journal of the Nigerian Society of Physical Sciences: Volume 6, Issue 2, May 2024

- Ibukun Akinsola, Aderemi Babatunde Alabi, Muibat A Soliu, Taiye Akomolafe, Optimization of Method and Components of Enzymatic Fuel Cells , Journal of the Nigerian Society of Physical Sciences: Volume 1, Issue 4, November 2019

You may also start an advanced similarity search for this article.