Isolation and investigation of the structure of silicon quantum dots from rice husk ultrafine silica for possible applications in nanoelectromechanical systems

Keywords:

Silicon quantum dots, Rice husk silica, Sol-gel, Magnesiothermic reductionAbstract

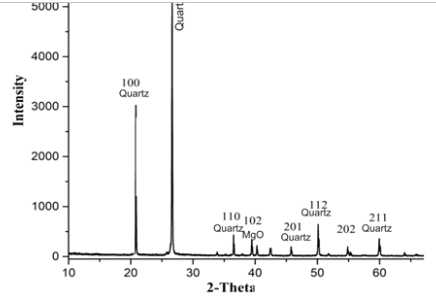

Silicon quantum dots (SiQDs) are nanostructure semiconducting crystalline particles of silicon, usually less than 10 nm in size. Usually, silicon is extracted from its oxide through a carbothermic process using electric submerged arc furnaces at temperatures exceeding 2000 ºC, a highly energy-intensive method and detrimental to silicon oxide's structural properties, resulting in carbon dioxide emissions. In this work, we propose a two-step green approach involving sol-gel synthesis and solid state magnesiothermic reduction at 700 ºC to produce silicon quantum dots from rice husk ash. This method prevents strain, fracture, and vaporization associated with direct reduction methods at higher temperatures, which emit greenhouse gases and vaporize silicon. The produced silicon quantum dots were characterized using Energy Dispersive Spectroscopy (EDS), Transmission Electron Microscopy (TEM), and X-ray Diffraction (XRD) techniques. A total total yield of 77.76% silicon, with average particle and crystallite sizes of 2.51 nm and 2.69 nm, respectively was observed. The material exhibited a dislocation density of 0.14 (14 %) lines/nm2, strain of 0.0467 (4.67%), stress of 7.94 GPa, Young modulus of 170 GPa, and energy density of 32.50 GJm-3. These indicate robust mechanical properties that suitable for nanoelectromechanical systems(NEMS) fabrication. In addition, this eco-friendly method used in this work utilizes rice husk silica which prevent the use of synthetic and harmful silica precursors. Thus, enhances sustainability and cost-effectiveness in accordance with green synthesis principles and the use of local resources.

Published

How to Cite

Issue

Section

Copyright (c) 2025 K. M. Omatola, A. D. Onojah, R. Larayetan, A. O. Ohiani, I. I. Oshatuyi, M. B. Ochang, O. Anawo, P. Abraham (Author)

This work is licensed under a Creative Commons Attribution 4.0 International License.