Potential of Anacardic Acid for Nanosized Cellulose Preparation Under Different Treatment Conditions

Keywords:

Anacardic acid, Cellulose, Nanosized cellulose, Ultrasonication, Reflux, Microwave irradiationAbstract

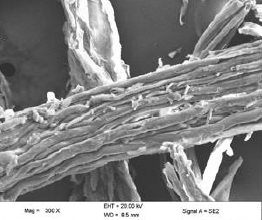

Herein, anacardic acid was applied for the preparation of nanosized cellulose using three different 11 treatment conditions including ultrasonication, microwave irradiation, and reflux. Physico-chemical 12 characterization was undertaken using FTIR, TEM, SEM, and XRD. FTIR, TEM, and SEM analyses 13 confirm the preparation of nanosized cellulose with similar chemical but different physical properties as 14 the cellulose starting material. In addition, calculated degrees of crystallinities from XRD data revealed 15 crystallinities of 53.9, 54.4, and 54.7 % for the nanosized cellulose prepared by ultrasonication (UNC), 16 microwave irradiation (MNC), and reflux (RNC) respectively, which all are higher than the 53.3 % of the 17 precursor cellulose. Overall, the study shows that anacardic acid holds potential for the preparation of 18 nanosized cellulose.

Published

How to Cite

Issue

Section

Copyright (c) 2022 Olugbenga O. Oluwasina, Abiodun D. Aderibigbe, Damilola C. Petinrin, Adeyemi S. Adebisi, Olayinka O. Oluwasina, Oluwasegun J. Wahab

This work is licensed under a Creative Commons Attribution 4.0 International License.

How to Cite

Similar Articles

- A. F. Afolabi, S. S. Oluyamo, I. A. Fuwape, Synthetic characterization and structural properties of nanocellulose from moringa oleifera seeds , Journal of the Nigerian Society of Physical Sciences: Volume 3, Issue 3, August 2021

- Olayinka Oluwaseun Oluwasina, Mochamad Zakki Fahmi, Olugbenga Oludayo Oluwasina, Enhancing cellulose fiber properties from chromolaena odorata and anana comosus through novel pulping chemical mixtures , Journal of the Nigerian Society of Physical Sciences: Volume 6, Issue 2, May 2024

- Chidi Duru, Ijeoma Duru, Chiagoziem Chidiebere, Virtual Screening of Selected Natural Products as Human Tyrosinase-Related Protein 1 Blockers , Journal of the Nigerian Society of Physical Sciences: Volume 3, Issue 3, August 2021

- K. K. Adama, I. B. Onyeachu, The corrosion characteristics of SS316L stainless steel in a typical acid cleaning solution and its inhibition by 1-benzylimidazole: Weight loss, electrochemical and SEM characterizations , Journal of the Nigerian Society of Physical Sciences: Volume 4, Issue 2, May 2022

- C. B. Adindu, S. C. Nwanonenyi, C. B. C. Ikpa, Experimental and computational studies of the corrosion inhibitive effects of Zingiber officinale rhizomes on mild steel corrosion in acidic solutions , Journal of the Nigerian Society of Physical Sciences: Volume 5, Issue 3, August 2023

- Selvaraju Sivamani, Marwan Ahmed Sulieman Al Aamri, Aseela Musalem Awad Anthroon Jaboob, Azeezah Mohammed Masoud Kashoob, Layal Kamall Abdullah Al-Hakeem, Mouna Salim Mhaad Said Almashany, Muna Ahmed Mohammed Safrar, Heterogeneous Catalyzed Synthesis of Biodiesel from Crude Sunflower Oil , Journal of the Nigerian Society of Physical Sciences: Volume 4, Issue 1, February 2022

- A. F. Afolabi, S. S. Oluyamo, I. A. Fuwape, Synthetic Characterization of Cellulose from Moringa oleifera seeds and Potential Application in Water Purification , Journal of the Nigerian Society of Physical Sciences: Volume 3, Issue 3, August 2021

- Sylvester J. Gemanam, Nursakinah Suardi, Barnabas A. Ikyo, Samson Damilola Oluwafemi, Terver Daniel, Samuel T. Kungur, Biostimulation Effects and Temperature Variation in Stimulated Dielectric Substance (Diabetic Blood Comparable to Non-Diabetic Blood) Based on the Specific Absorption Rate (SAR) in Laser Therapy , Journal of the Nigerian Society of Physical Sciences: Volume 3, Issue 2, May 2021

- Daud Olaoluwa, Abdulhadi E. Abdulmalik, Taoreed A. Muraina, Sadisu Girigisu, Ayo F. Balogun, Dissolution of a Nigerian sourced Muscovite ore for use as an ingredient in paint production , Journal of the Nigerian Society of Physical Sciences: Volume 2, Issue 3, August 2020

- Yaulande Douanla Alotse, Mamadou Ossénatou, Dembele André, Lenouo André, Bivariate and Partial Wavelet Coherence analysis of aerosols impact on Global Horizontal Irradiation in Far-North and Littoral regions of Cameroon , Journal of the Nigerian Society of Physical Sciences: Volume 5, Issue 1, February 2023

You may also start an advanced similarity search for this article.