Effect of radial non-uniformity on mechanical response of functionally graded discs

Keywords:

Non-homogeneous, FGM, Stresses, Strains, Thermoelasticity, DisplacementAbstract

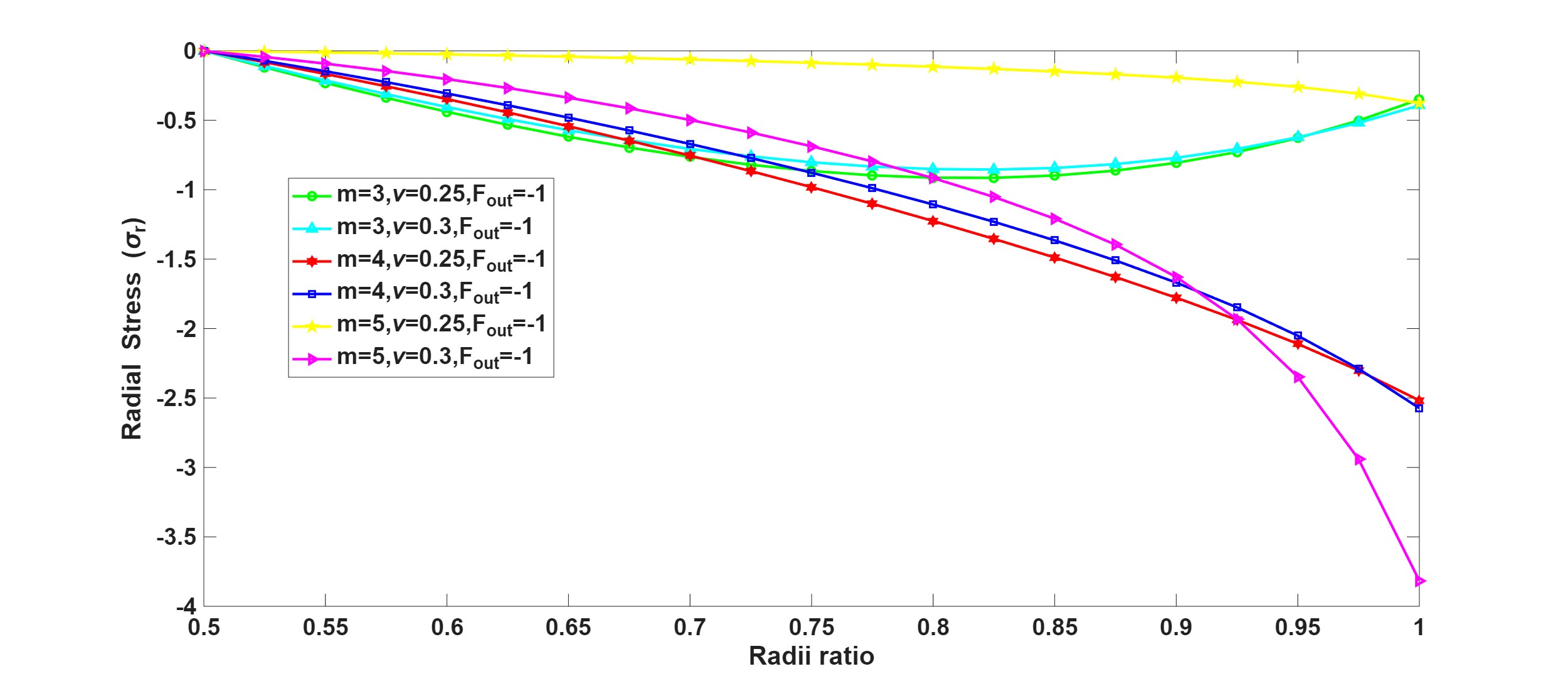

This study investigates the stress distribution in functionally graded material (FGM) discs composed of compressible and incompressible constituents, subjected to nonhomogeneity and external loading. Analytical results are presented for radial and tangential stresses as functions of the radii ratio r/b the gradation parameter m, and Poisson’s ratio $\nu$. However, the combined effect of compressibility and material gradation on the stress response of discs remains insufficiently explored, particularly in cases where both compressible (\nu < 0.5) and incompressible (\nu \rightarrow 0.5) material behaviors are considered under identical loading conditions. The methodology is designed to systematically evaluate how radial stress (\sigma_r) and tangential stress (\sigma_\theta) evolve across the disc geometry in response to the combined influences of material gradation and volumetric compressibility. Figures are generated by MATLAB to provide comparative insights, separating compressible and incompressible cases, and highlighting the stress sensitivity to parameter variations. The focus of the investigation is twofold. First, the study seeks to establish the relationship between Poisson’s ratio and stress magnitudes, particularly assessing whether compressible materials exhibit sharper stress gradients that could lead to structural instability. Second, the work examines the extent to which nonhomogeneity, represented by the parameter m, modifies these trends in both compressible and incompressible regimes. Furthermore, by delineating the contrasting behavior of compressible and incompressible FGMs, the study provides a decision-making basis for selecting appropriate material gradations in scenarios where crack initiation, fatigue resistance, or tensile failure are of concern. Thus, the present work sets out to systematically examine how compressibility and gradation interact to determine stress responses in FGM discs, with the ultimate objective of offering practical guidelines for the safe and efficient application of these advanced materials in engineering design.

Published

How to Cite

Issue

Section

Copyright (c) 2025 Namarta Singh, Jatinder saini (Author)

This work is licensed under a Creative Commons Attribution 4.0 International License.

How to Cite

Similar Articles

- Pragati, Rajneesh Kumar, Sachin Kaushal, Effect of a moving thermal load in a modified couple stress medium with double porosity and hyperbolic two-temperature theory , Journal of the Nigerian Society of Physical Sciences: Volume 8, Issue 1, February 2026 (In Progress)

- G. Kamarajan, D. Benny Anburaj, V. Porkalai, A. Muthuvel, G. Nedunchezhian, Effect of temperature on optical, structural, morphological and antibacterial properties of biosynthesized ZnO nanoparticles , Journal of the Nigerian Society of Physical Sciences: Volume 4, Issue 3, August 2022

- U. E. Edeke, U. N. Bassey, Some properties of convolution and spherical analysis on the Euclidean motion group , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 2, May 2025

- Abdulwasiu Abdurrahman, Saidu Muhammad Waziri, Olusegun Ayoola Ajayi, Fadimatu Nyako Dabai, Optimization of Potassium Carbonate-based DES as Catalyst in the Production of Biodiesel via Transesterification , Journal of the Nigerian Society of Physical Sciences: Volume 5, Issue 1, February 2023

- Kenneth Christopher Ugwoke, Nnanna Nwojo Agwu, Saleh Abdullahi, Artificial potential field path length reduction using Kenneth-Nnanna-Saleh algorithm , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 3, August 2025

You may also start an advanced similarity search for this article.