Development and validation of hybrid drying kinetics models with finite element method integration for black paper in a v-groove solar dryer

Keywords:

Black pepper, Solar drying, Hybrid drying models, Finite element method, CurveExpert professionalAbstract

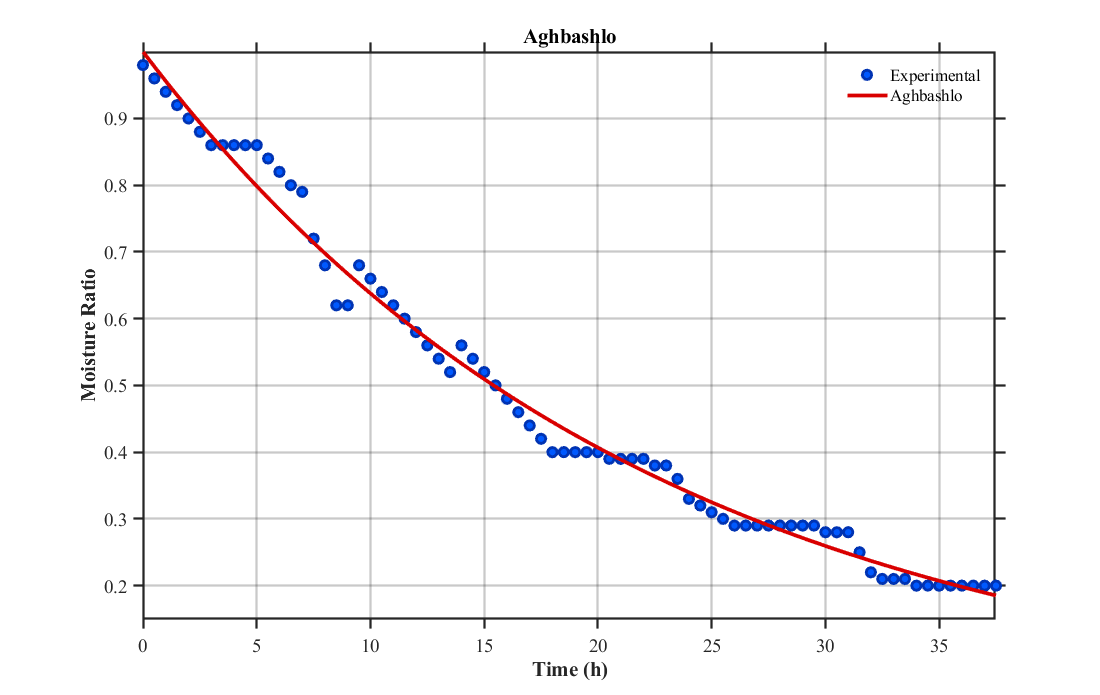

Preserving agricultural products requires drying techniques to avoid spoilage and financial setbacks. Sun drying is unreliable because of changing weather conditions; hybrid solar dryers provide an option. However, it is not easy to forecast the drying process of crops such, as black pepper due to its drying characteristics. This research examines how accurately different models predict the drying process of black pepper in a v Groove Hybrid Solar Dryer using a modeling framework and a Finite Element Method (FEM) inspired approach that is newly developed. Black pepper was dried for four days, with the moisture ratio data collected every 30 minutes from 8 AM to 5 PM. Twenty-seven drying kinetics models were tested on the data, with the Alibus model, Aghbashlo, and Infiltration Approximation models being the three best performers. To improve the accuracy of predictions, a total of 220 hybrid models were created by merging pairs of the 11 best-performing models using a specialized formula based on weights. The analysis indicated that more than thirty (30) hybrid models performed better than single models with Hybrid M28 (combining Logarithmic and Alibus), Hybrid M38 (pairing Lewis and Alibus), and Hybrid M101 (merging Infiltration Approximation and Kaleemullah), showing exceptional results. Furthermore, a model based on FEM was developed and validated using MATLAB and CurveExpert Professional to account for the physical diffusion characteristics. While it demonstrated good alignment with the experimental data, it equally acted as a solid foundation based on physics principles. The results highlighted the capability of combining hybrid and FEM based models to better understand intricate drying patterns in a more efficient way which can lead to improved solar drying system designs with enhanced reliability for future optimization efforts, across various crop types.

Published

How to Cite

Issue

Section

Copyright (c) 2025 Ibrahim Adamu Mohammed, Majid Khan Majahar Ali, Sani Rabiu, Raja Aqib Shamim, Shahida Shahnawaz (Author)

This work is licensed under a Creative Commons Attribution 4.0 International License.

How to Cite

Most read articles by the same author(s)

- O. J. Ibidoja, F. P. Shan, Mukhtar, J. Sulaiman, M. K. M. Ali, Robust M-estimators and Machine Learning Algorithms for Improving the Predictive Accuracy of Seaweed Contaminated Big Data , Journal of the Nigerian Society of Physical Sciences: Volume 5, Issue 1, February 2023

- Xiaojie Zhou, Majid Khan Majahar Ali, Farah Aini Abdullah, Lili Wu, Ying Tian, Tao Li, Kaihui Li, Air quality prediction enhanced by a CNN-LSTM-Attention model optimized with an advanced dung beetle algorithm , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 3, August 2025

- Shaymaa Mohammed Ahmed, Majid Khan Majahar Ali, Raja Aqib Shamim, Integrating robust feature selection with deep learning for ultra-high-dimensional survival analysis in renal cell carcinoma , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 4, November 2025

- Paavithashnee Ravi Kumar, Majid Khan Majahar Ali, Olayemi Joshua Ibidoja, Identifying heterogeneity for increasing the prediction accuracy of machine learning models , Journal of the Nigerian Society of Physical Sciences: Volume 6, Issue 3, August 2024

- Raja Aqib Shamim, Majid Khan Majahar Ali, Optimizing discrete dutch auctions with time considerations: a strategic approach for lognormal valuation distributions , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 1, February 2025

- Shaymaa Mohammed Ahmed, Majid Khan Majahar Ali, Arshad Hameed Hasan, Evaluating feature selection methods in a hybrid Weibull Freund-Cox proportional hazards model for renal cell carcinoma , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 3, August 2025

- Nahid Salma, Majid Khan Majahar Ali, Raja Aqib Shamim, Machine learning-based feature selection for ultra-high-dimensional survival data: a computational approach , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 3, August 2025

- Chuchu Liang, Majid Khan Majahar Ali, Lili Wu, A novel multi-class classification method for arrhythmias using Hankel dynamic mode decomposition and long short-term memory networks , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 2, May 2025

- xiaojie zhou, Majid Khan Majahar Ali, Farah Aini Abdullah, Lili Wu, Ying Tian, Tao Li, Kaihui Li, Implementing a dung beetle optimization algorithm enhanced with multi-strategy fusion techniques , Journal of the Nigerian Society of Physical Sciences: Volume 7, Issue 2, May 2025

- Raja Aqib Shamim, Majid Khan Majahar Ali, Mohamed Farouk Haashir bin Hamdullah, Computational optimization of auctioneer revenue in modified discrete Dutch auctions with cara risk preferences , Journal of the Nigerian Society of Physical Sciences: Volume 8, Issue 1, February 2026 (In Progress)